摘要

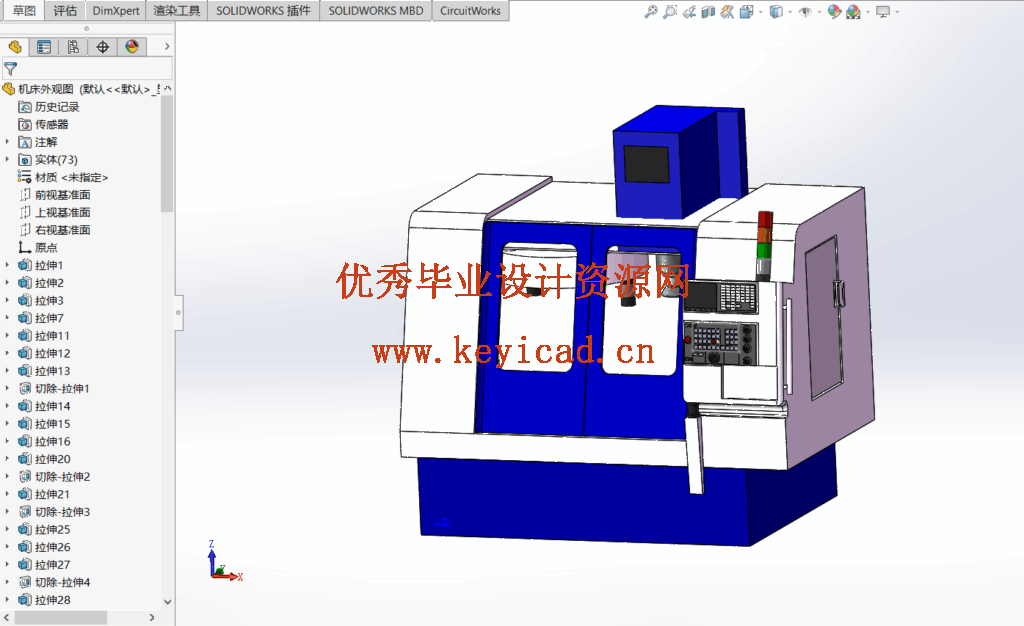

本次设计通过对现有加工中心的分析研究,提出一种新的设计方案,其自动化程度更高,结构也相对比较简单.这一点在论文会得以体现.本方案中,主轴箱采用交流调速电机实现无级变速,在X、Y、Z三个方向上的进给运动均采用滚珠丝杠,而动力则由步进电动机通过调隙齿轮来传递,并且采用单片机进行数字控制.

控制系统采用MCS-51系列单片机,通过扩展程序存储器、数据存储器和I/O接口实现硬件电路的设计.论文中也对软件系统的设计做出了相关说明.

关键词:交流调速电机 滚珠丝杠 步进电机 单片机系统扩展

目录

前言······················································1

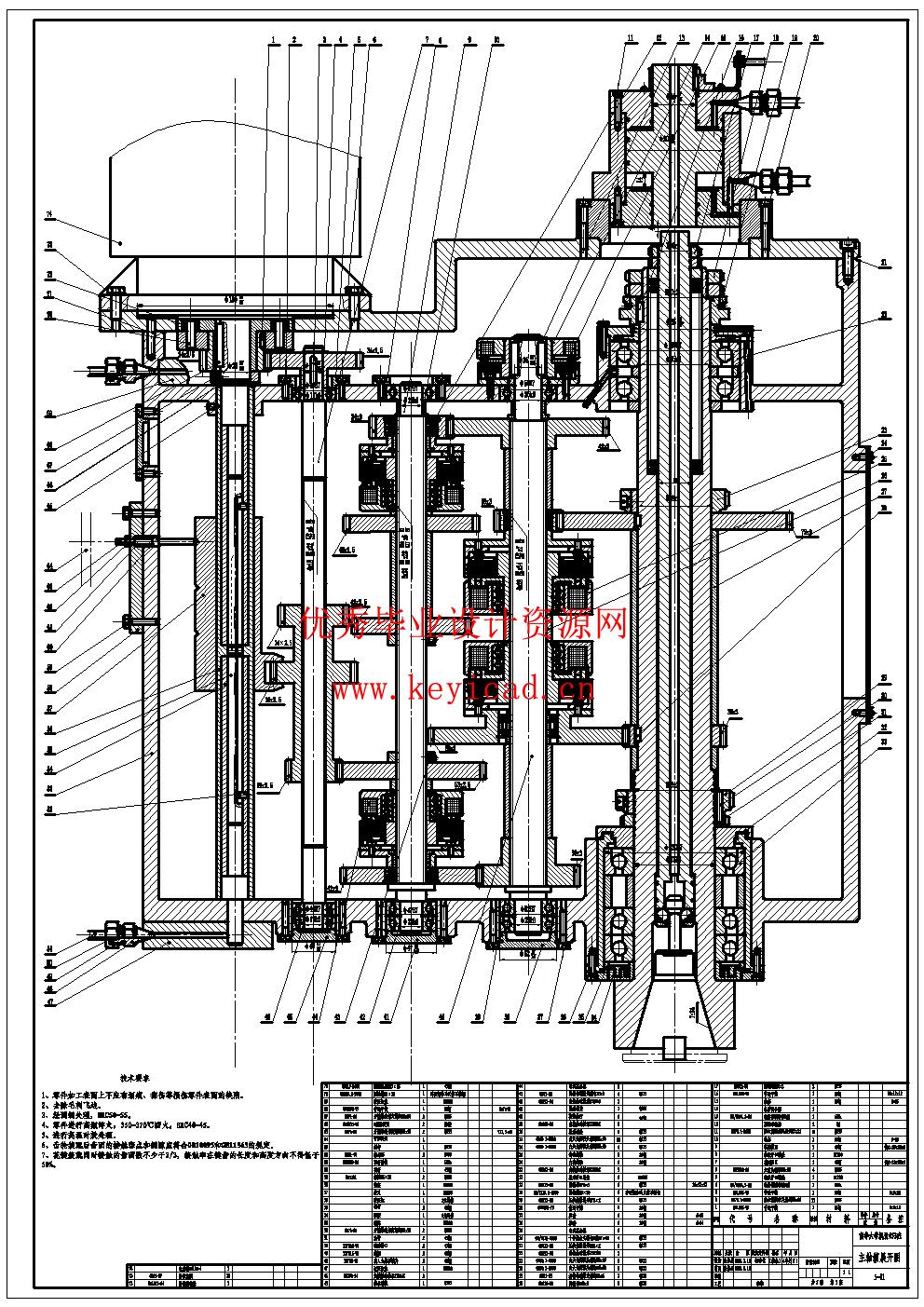

1、机床总体方案设计·······································1

1.1 机床总体尺寸参数的选定·····························1

1.2 机床主要部件及运动方式的选定·······················2

1.3 机床总体布局的确定·································3

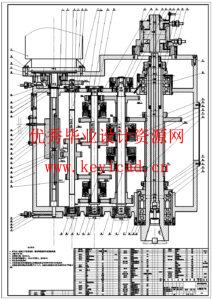

2、主传动的设计计算·······································8

2.1 电机的选择·········································8

2.2 齿轮传动的设计计算·································9

2.3 轴的设计计算······································13

2.4 离合器的选用······································21

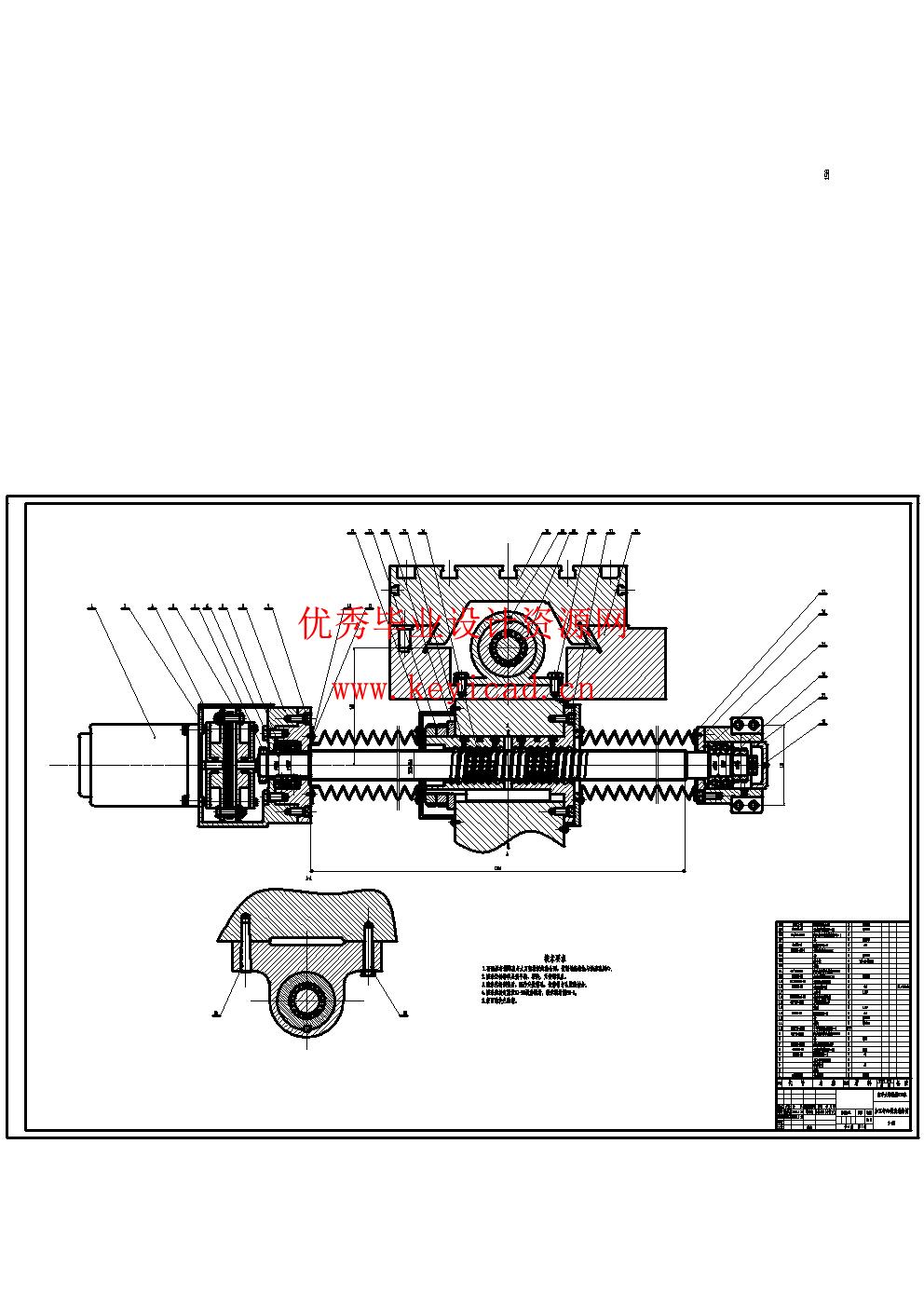

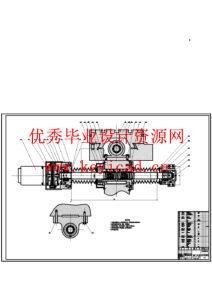

3、进给系统的设计计算···································22

3.1 概述··············································22

3.2 设计计算··········································22

3.3 工作台部件的装配图设计····························29

3.4 滚珠丝杠螺母副的承载能力的校验····················30

3.5 计算机械传动系统的刚度····························31

3.6 驱动电动机的选型与计算····························33

3.7 机械传动系统的动态分析····························36

3.8 机械传动系统的误差计算与分析·····················37

3.9 确定滚珠丝杠螺母副的精度等级和规格型号············38

3.10 滚珠丝杆副的预紧方式·····························38

3.11 齿轮传动消隙····································39

4、控制系统的设计········································39

4.1 控制系统总体方案的拟订····························39

4.2 总控制系统硬件电路设计····························39

参考文献·················································56

谢 辞················································57

科技译文·················································58

说明书

三维模型

CAD图纸

文件列表

下载链接